| Dryer | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

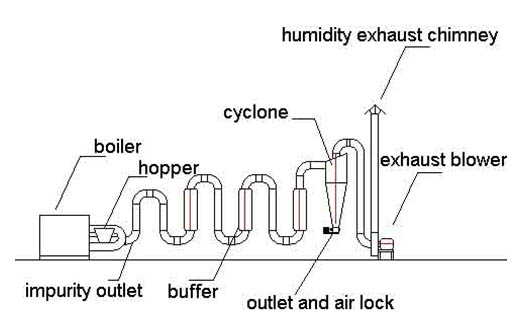

Working Principle: Wet material is input into the hopper. The stove(boiler)

generates hot air, hot air mixed with wet sawdust and then

sucked into the pipes by the exhaust blower(fan) , flowing

and go though the curving pipes and buffer(drying chamber)

of dryer, thus the wet sawdust is dried, and the dried sawdust

is discharged from the outlet with air lock. The feeding of fuel for boiler is by manual.The fuel can be wood waste like tree branch, tree trimmings, wood chips, coal or any waste that can burn (But Gas or Oil is impossible for the boiler now). |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sawdust Dryer Model HGJI |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Drawing Of Sawdust Dryer Model HGJII |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (1) Dryer model HGJ-I, HGJ-II, HGJ-III

for lower moisture content 12-25% The Moisture reducing rate of the dryer HGJ-I, HGJ-II, HGJ-III is 8-12%. This dryer is equipped with one hot air boiler, it is suitable for drying raw material with moisture content less than 20-25%.If the moisture content of the raw material is higher than that, it will need several times of drying to achieve the requested moisture content for briquetting.

(2) Twin boiler dryer model NHGJ-I, NHGJ-II, NHGJ-III for higher moisture content 20-50% Twin boiler dryer is a newly developed dryer with two hot air boilers, it is suitable for drying raw material with moisture content of 20% -50%, it can reduce moisture from 20%-50% to 8-12% only one passage or one time. PS: For moisture of entering material 20-35%: Use only one boiler

|

- Introduction Of Project of Biomass Briquette Machine

- Wood Crusher

- Dryer

- Biomass Briquetting Press

- Thermal Shrink Wrapping Machine

Street Address :Suite C, 4/F, Jinhao Business Bld., Renmin Rd. Anyang, Henan, P.R.C.